Si vos postulo si auxilium, placere sentire liberum contactus nobis

LENTITUDO

LENTITUDO

- Silver Alloy Electrical Contact Materials

- Aeris Alloy Electrical Contact Materials

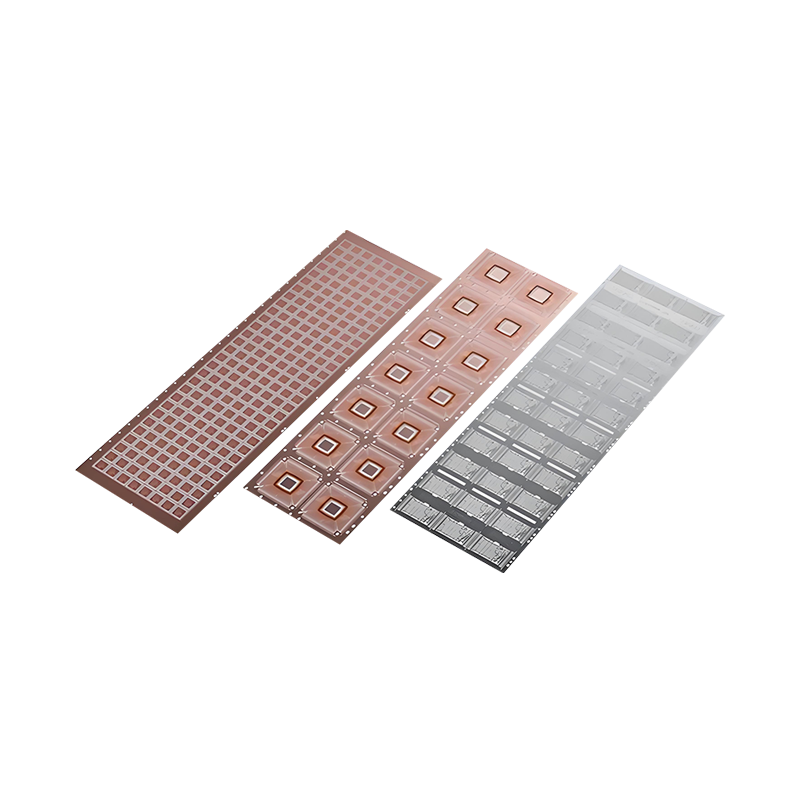

- Multi iacuit compositum materiae

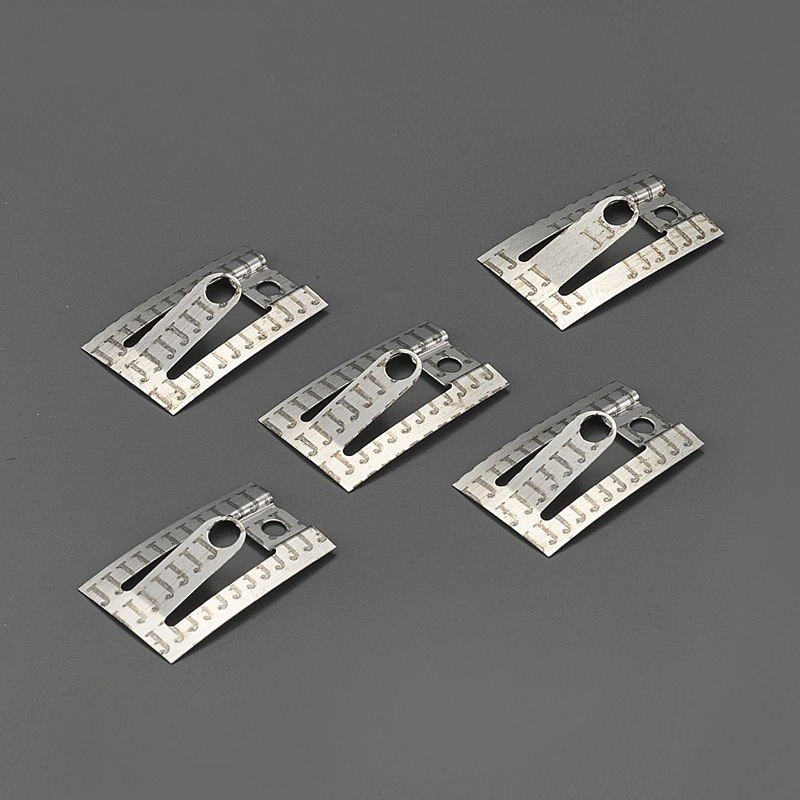

- Special genus filum

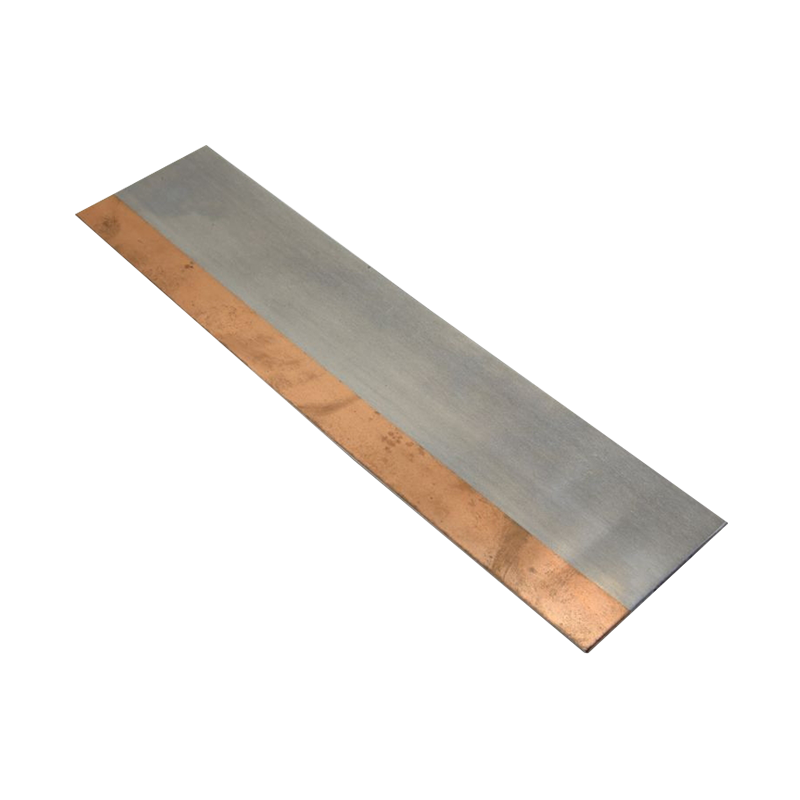

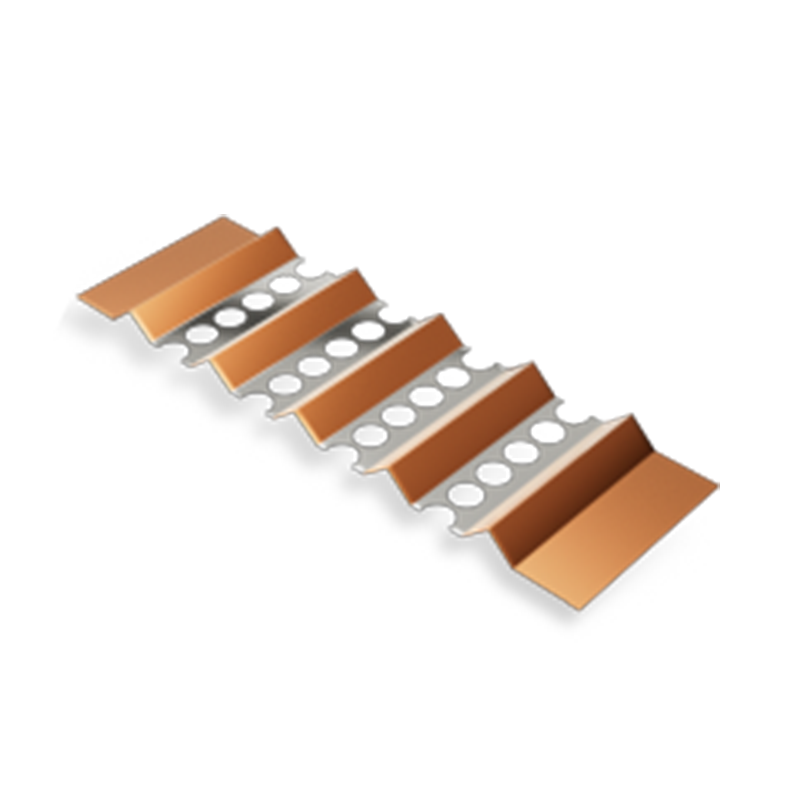

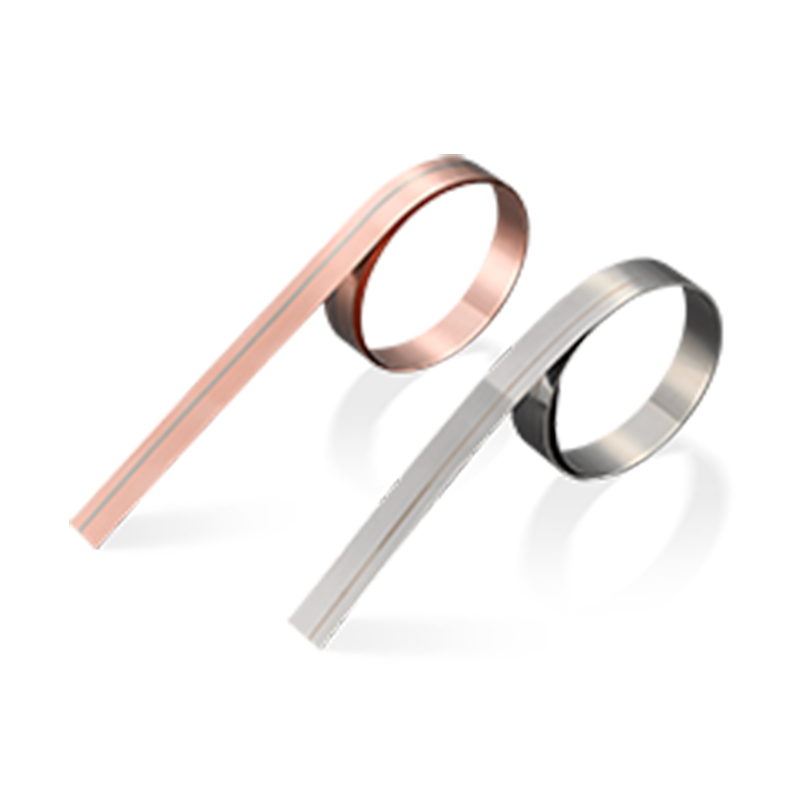

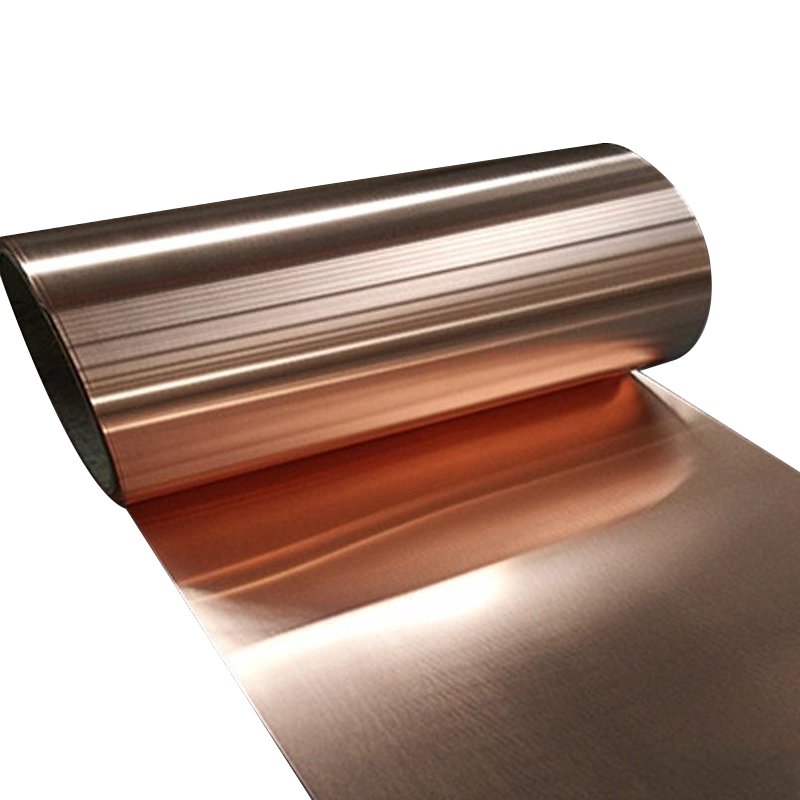

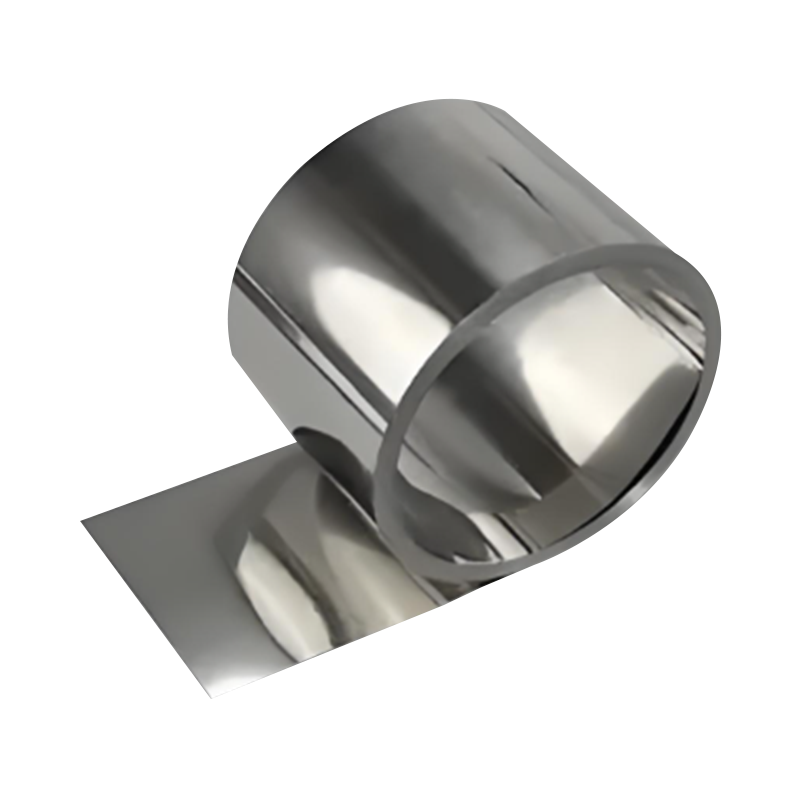

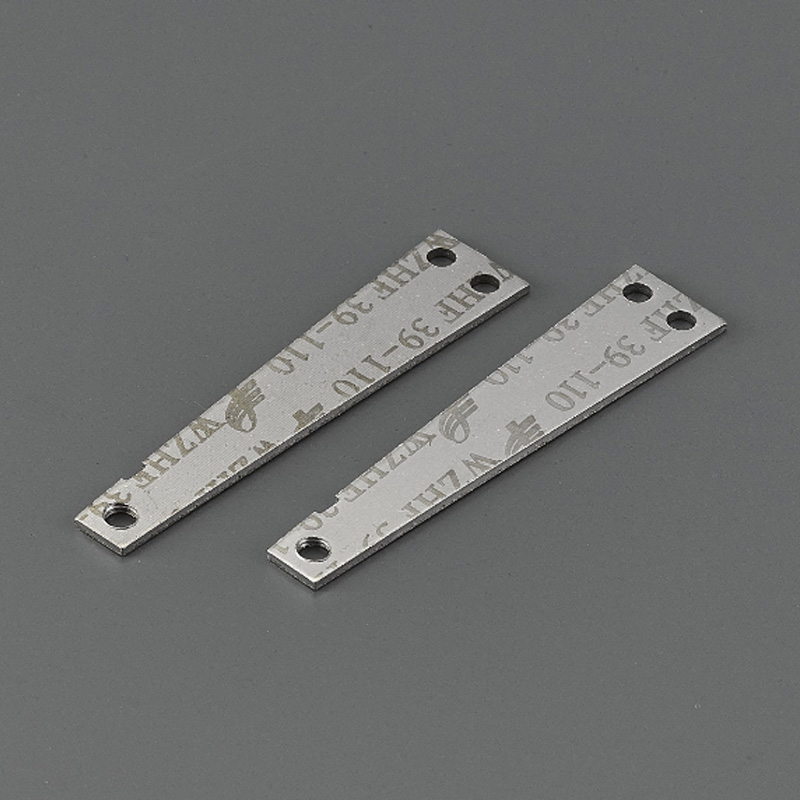

- Thermal Bimetal Material

- Aeris ferro compositum materia

- Aeris Aluminium composita materia

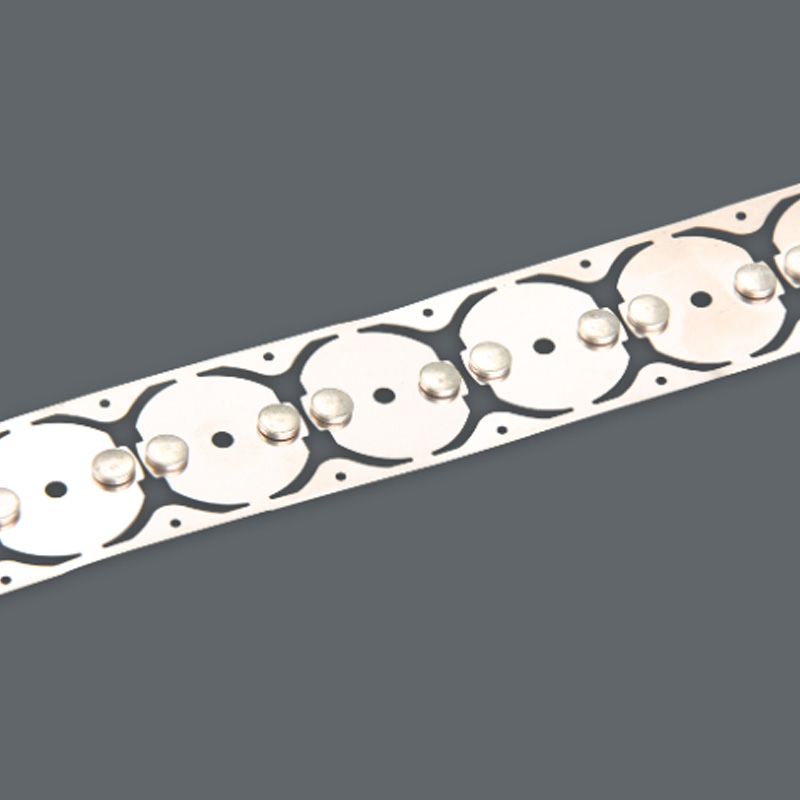

- Argentei aeris composita materia

- Aeris Nickel Composita Material

- Aluminium nickel composita materia

- Aluminium Steel Composita Material

- Nobili metallum complex

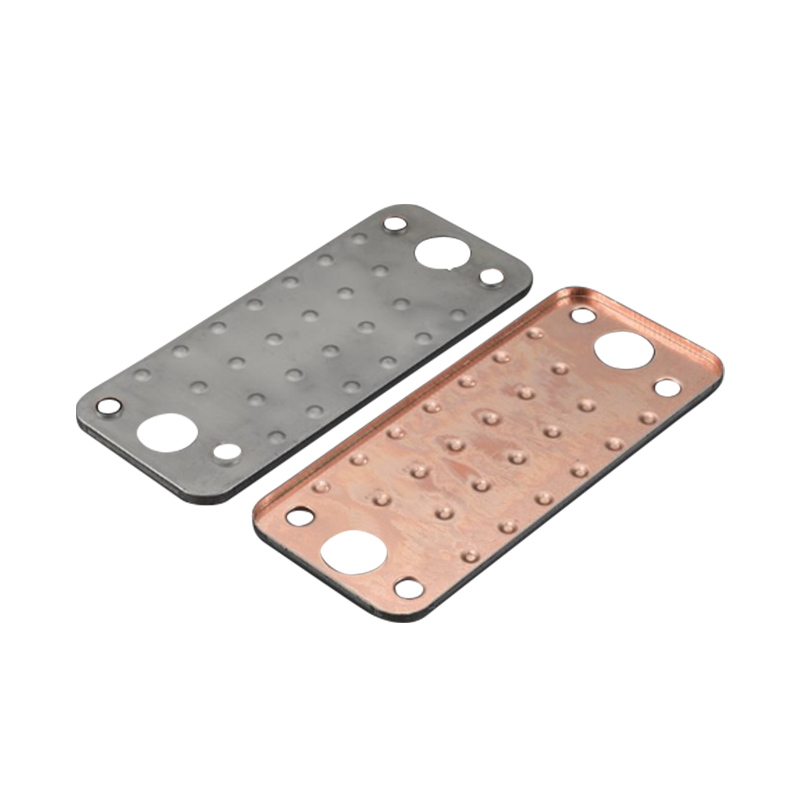

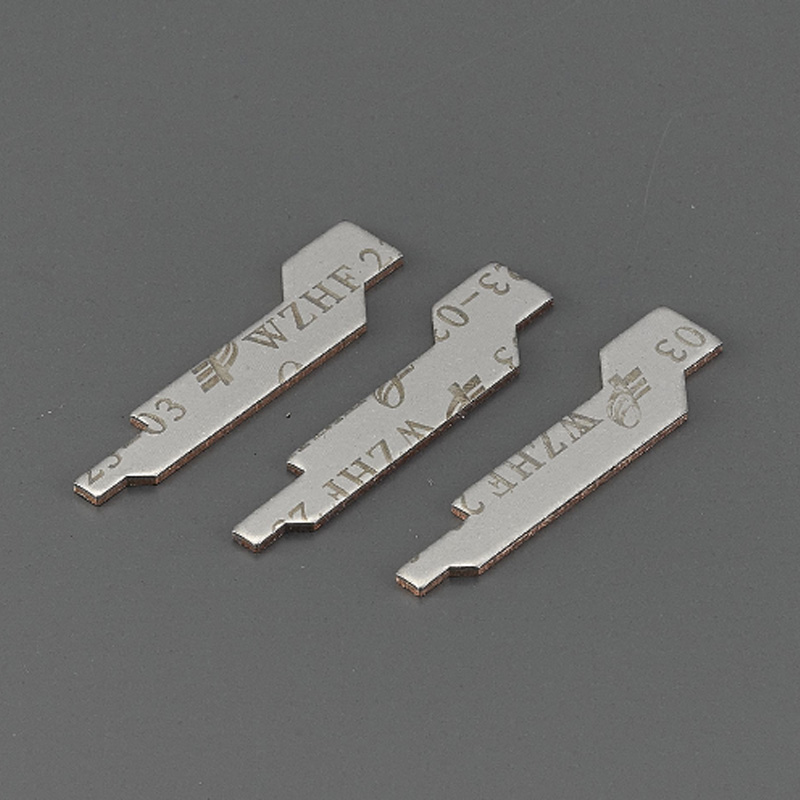

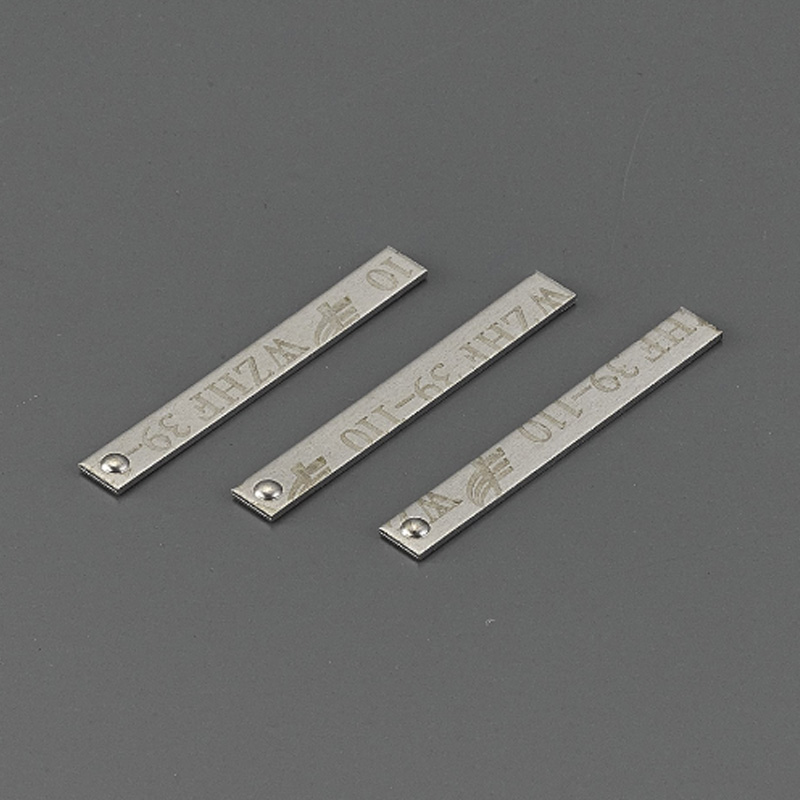

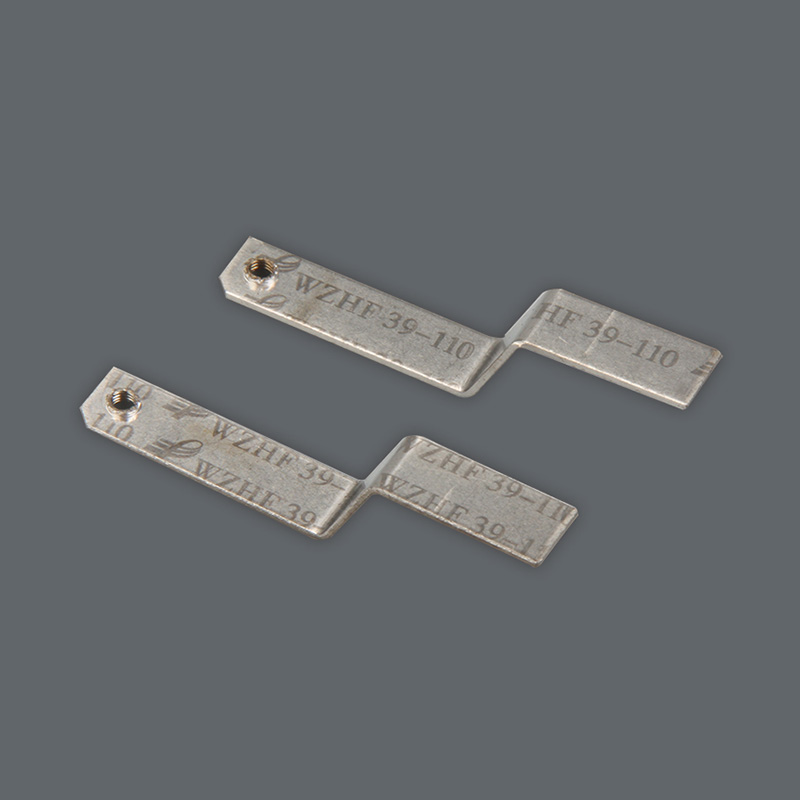

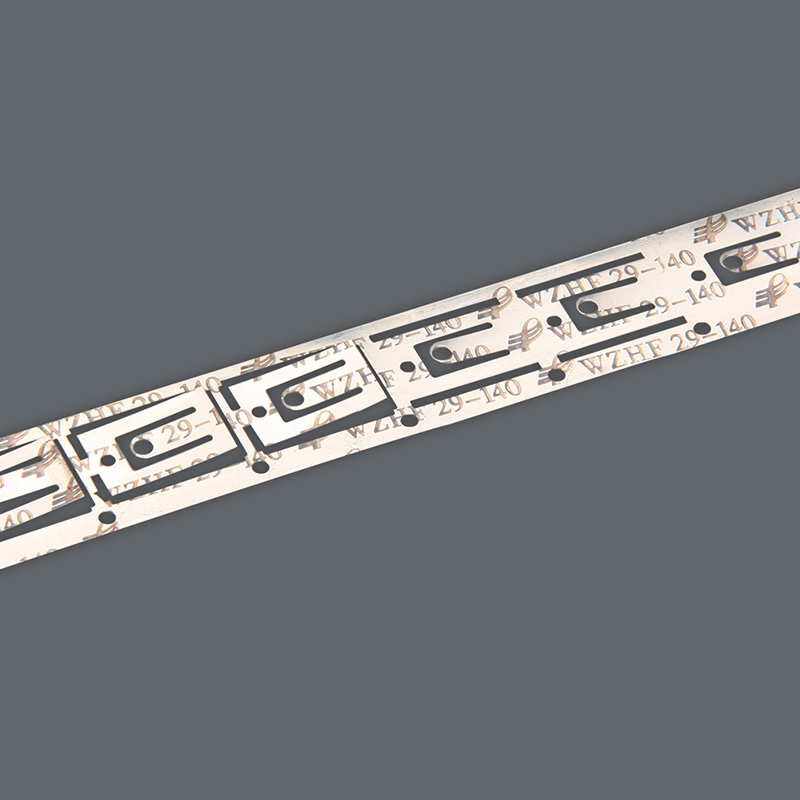

Thermal Bimetal Material

InquisitioA thermal bimetallic sheet est relative simplex automatic imperium component ad consequi temperatus imperium. Est ex duabus stratis metallis (vel Alloys) cum diversis coefficientes scelerisque expansion. Et iacuit cum magna scelerisque expansion coefficient dicitur activae iacuit, et iacuit cum parva scelerisque expansion coefficiens dicitur passivum. Cum scelerisque bimetal caletur longitudinem liberi expansionem activae layer maius quam passivae iacuit, sed duo stratis firmiter bonded simul, thermal bimetal ad arcus. Contrarium est cum refrigeratione. Hoc proprium potest esse creare scelerisque relationes. Communiter in motricium overload praesidium, dolor domos, temperatus sensoriis et protectores, automobiles et aliis agris.

| Grades | Materia | Crassities | Densitas |

| 5j20110 | DCCXXI / Ni36 | 0.1 ~ 2.5mm | 7.70g / cm 3 |

| 5J1480 | CCXXIII / Ni36 | 0.1 ~ 2.5mm | 8.03G / cm 3 |

| 5j1580 | CCVI / Ni36 | 0.1 ~ 2.5mm | 8.10G / cm 3 |

| 5j1070 | CCLVIII / Ni42 | 0.1 ~ 2.5mm | 8.03G / cm 3 |

| 5j1306a | CCVI / cu / ni36 | 0.1 ~ 2.5mm | 8.30G / cm 3 |

| 5j1411a | CCVI / cu / ni36 | 0.1 ~ 2.5mm | 8,20g / cm 3 |

| 5j1440a | CCXXIII / Ni / Ni36 | 0.1 ~ 2.5mm | 8.03g / cm 3 |

| 5j1440b | CCXXIII / Ni / Ni36 | 0.1 ~ 2.5mm | 8.03G / cm 3 |

| Grades | Temperatus curvaturae | Specifica | Modulum elasticitatis | Resistentia | Temperature range |

| 10-90 ℃ X10 ^ -6 / ° C | 20-100 ℃ X10 ^ -6 / ° C | N / mm 2 (X10 ^ V) | μωxcm | ℃ | |

| 5j20110 | 39.4 | 20.5 | 1.38 | 112.2 | -20 ~ CC |

| 5J1480 | 27 | 14.3 | 1.72 | 79 | -70 ~ CCCLXX |

| 5j1580 | 28.5 | 15.5 | 1.7 | 78 | -70 ~ CCCL |

| 5j1070 | 20.3 | 9.9 | 1.72 | 71 | -70 ~ DXL |

| 5j1306a | 25.6 | 13.5 | 1.62 | 5.8 | -70 ~ CCLX |

| 5j1411a | 27.6 | 14.9 | 1.65 | 10.5 | -70 ~ CC |

| 5j1440a | 26.5 | 14 | 1.76 | 41.6 | -70 ~ CCCLXX |

| 5j1440b | 26.5 | 14 | 1.76 | 41.6 | -70 ~ CCCLXX |

| Comparatio grades | |||

| GB / T4461 (Sina) | Laudate MDCCXV (Germania) | ASTM B388 (USA) | FEPAC (Sina) |

| 5j20110 | Tb20110 | TM-II | 721-110 FPA |

| 5J1480 | TB140 / LXXX | TM-I | FPA 223-80 |

| 5j1580 | Tb1578 | TM, XXIX | FPA 206-78 |

| 5j1070 | Tb0965 | TM-XXI | FPA 181-70 |

| 5j1306a | Tb1406 | / | Fpa 206-6a |

| 5j1411a | Tb1511 | / | FPA 206-11 |

| 5j1440a | / | / | 206-40 FPA |

| 5j1440b | / | TM-XIV | FAA 223-40 |

Wenzhou Hongfeng Electrical Alloy Co., Ltd. (Hereñafter ad quod "Wenzhou Hongfeeng"), Foil Foil Metals, Metal Customers et Development ut pars fabrica et intelligentes vestibulum. Noster products sunt late applicantur in industriae vestibulum, intelligentes transportation systems, dolor domos, communicationis notitia, aerospace, Mining, machinery Service, Effectly ad Customer Service, et Delicta Delivery: In addition, possumus etiam providere professionalem materiam consilio, processus optimization, sample praeparatione temptationis, massa productio copia, et technica firmamentum per officia ut professional material consilio, processus optimization et technica. Occursum Customer indiget summus perficientur stanica materiae.

-

Materials Design

Materials Design

Et developmentDesign et progressionem de novus mixturae muneris composita materiae potest ferri ex ut mos necessitates et applicationem elit.

-

Processu

Processu

OptimizationIn vestibulum processus of novus Alloy muneris compositum materiae potest esse optimized pro customers.

-

PRAECEPTIO

PRAECEPTIO

Et temptationisNon possum providere customers cum sample praeparatio et testing servicia pro novus mixturae muneris composita materiae.

-

Moles productio

Moles productio

SuppleSemel novus massa composita materials sunt massa, produci et praebere firmum et reliable copia.

-

Support technica

Support technica

Et consultingHongfeng potest etiam providere pertinet technica firmamentum et consulting servitiis ad customers.

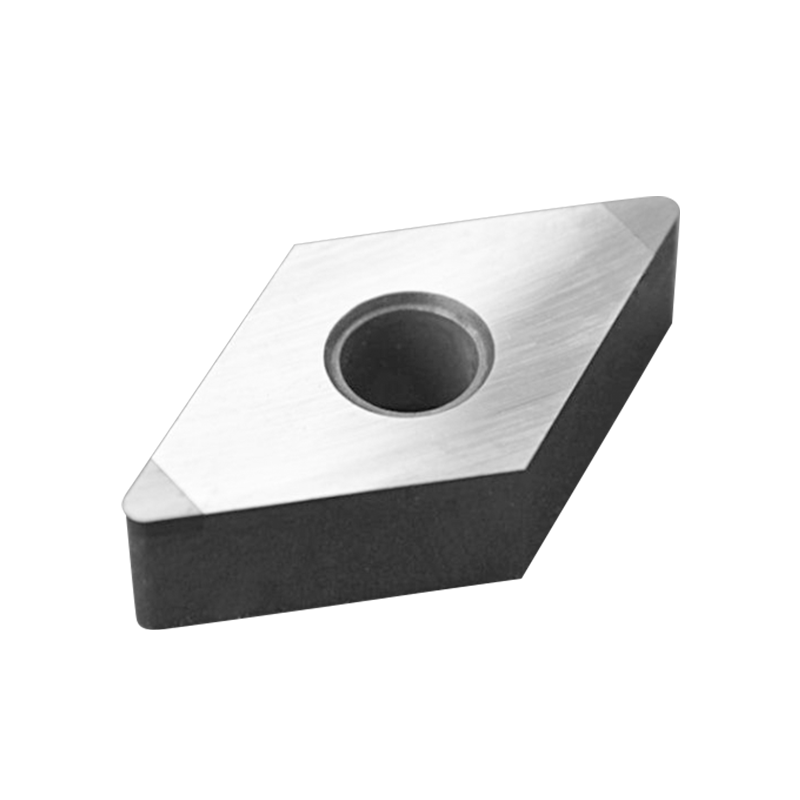

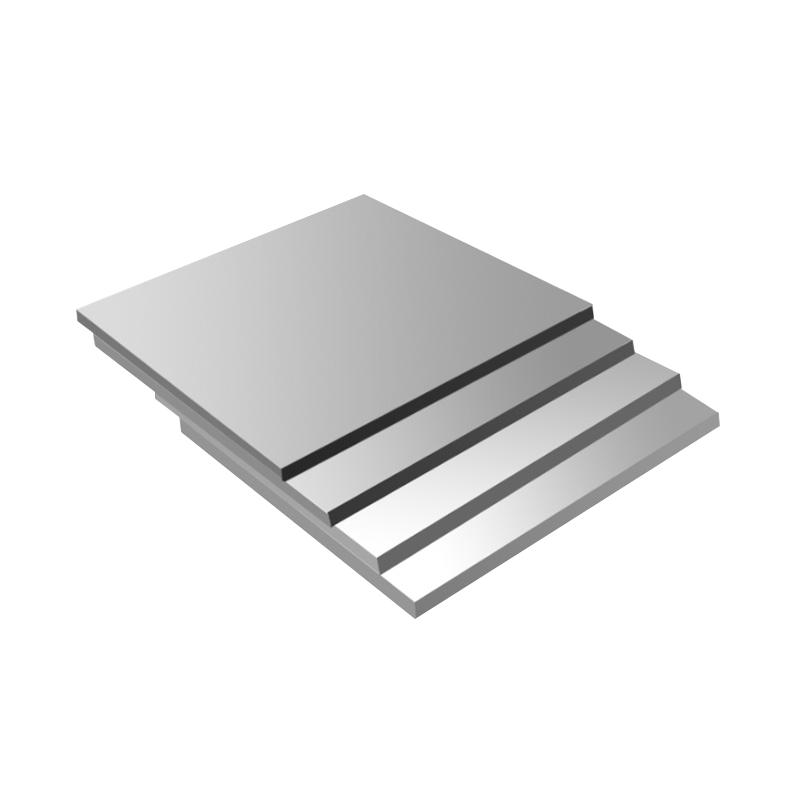

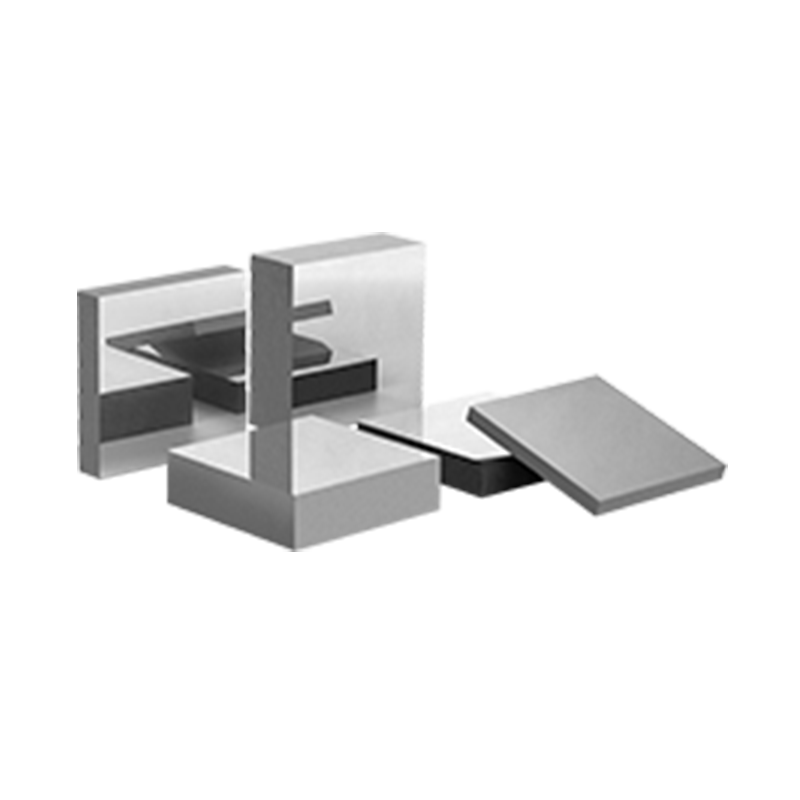

Ad perficientur Tungsten Carbide laminis est graviter motus per peccatum in processu usus ...

Introductio Tungsten carbide vectes et virgas sunt late in industries requiring ex...

Introductio Tungsten Carbide laminis Sunt machinati components factum ex composita mater...

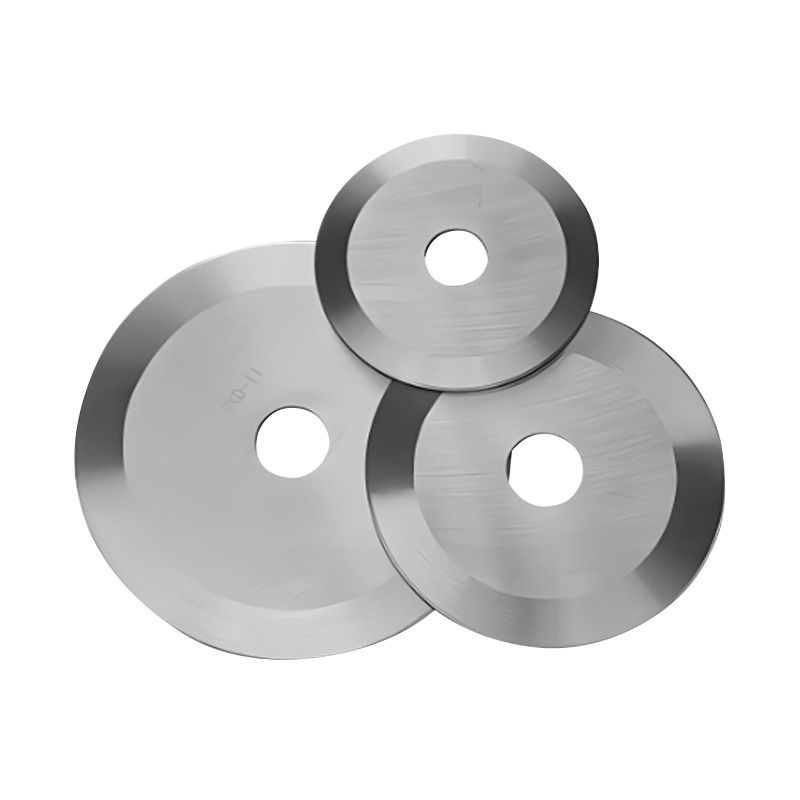

Tungsten Carbide Burgensis sunt Gyratorius Cutting Tools in amplis industrialis applications post...

In vestibulum mundi, qualis imperium Frigus diei Et fasteners non producendum est critica ...

- Tel:

86-18857735580 - E-mail:

[email protected]

- Add:

No. (V) DC, oujin Avenue, Wenzhou Marine Economic Development Demonstratio Zonam, Zhejiang Province, Sina