Si vos postulo si auxilium, placere sentire liberum contactus nobis

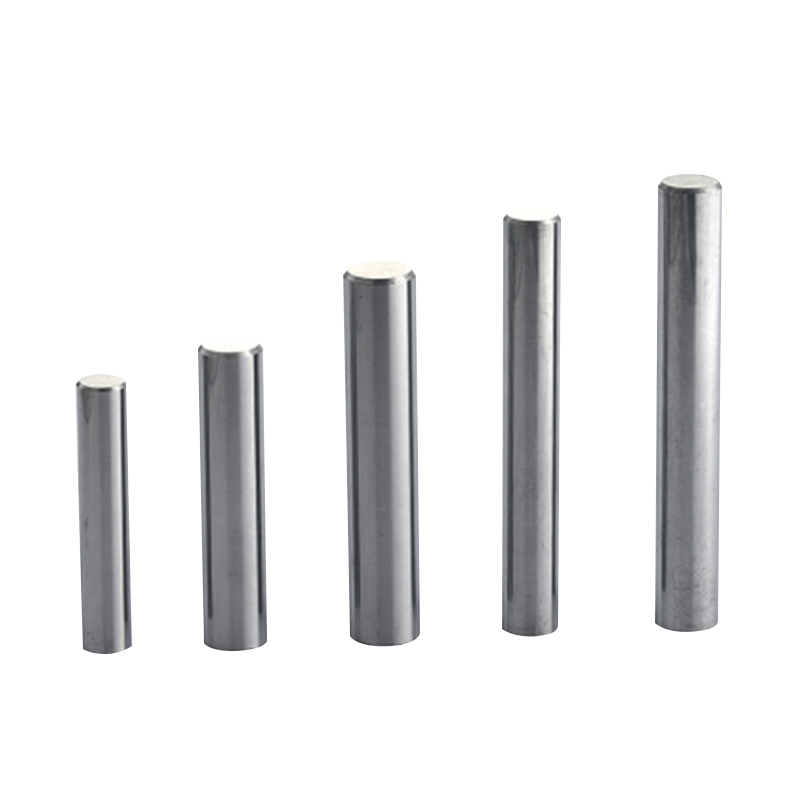

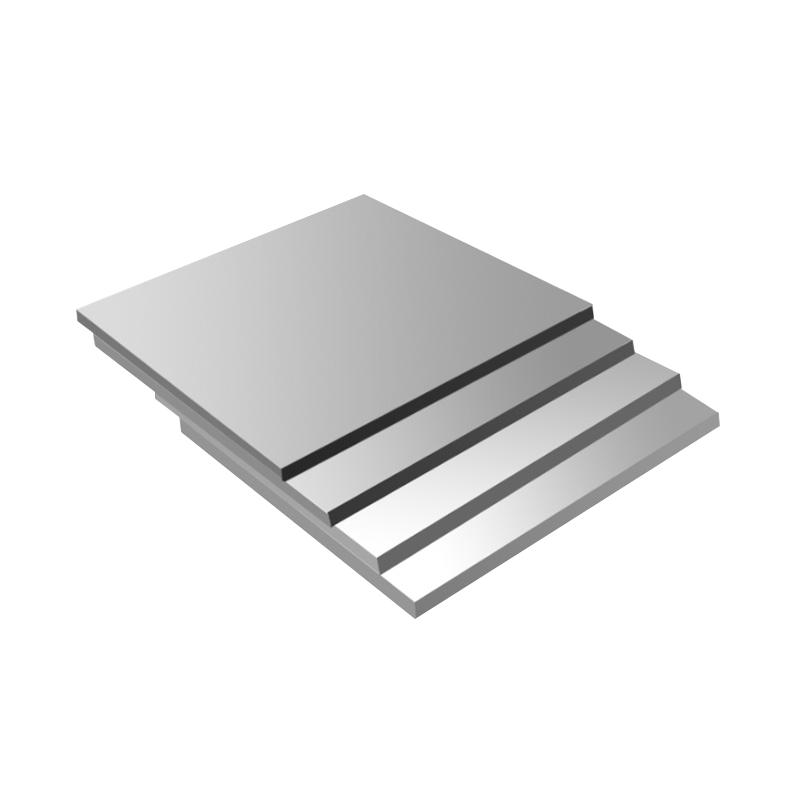

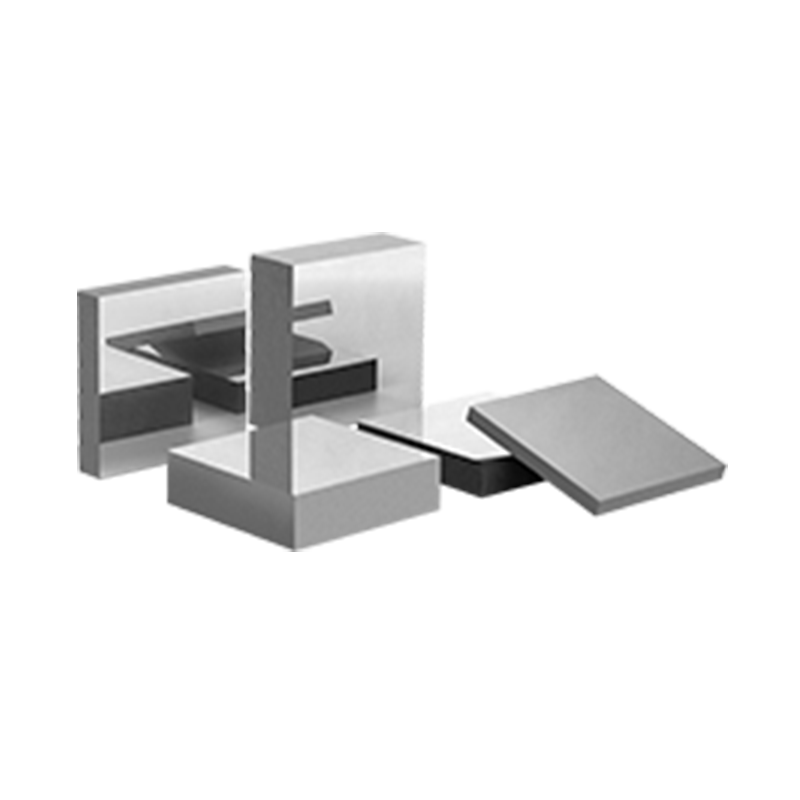

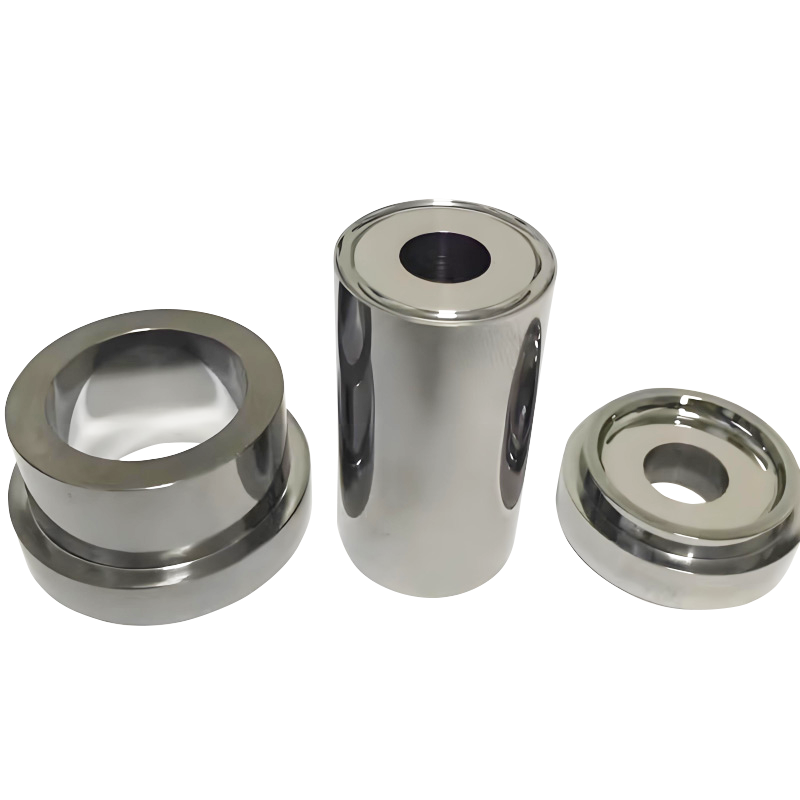

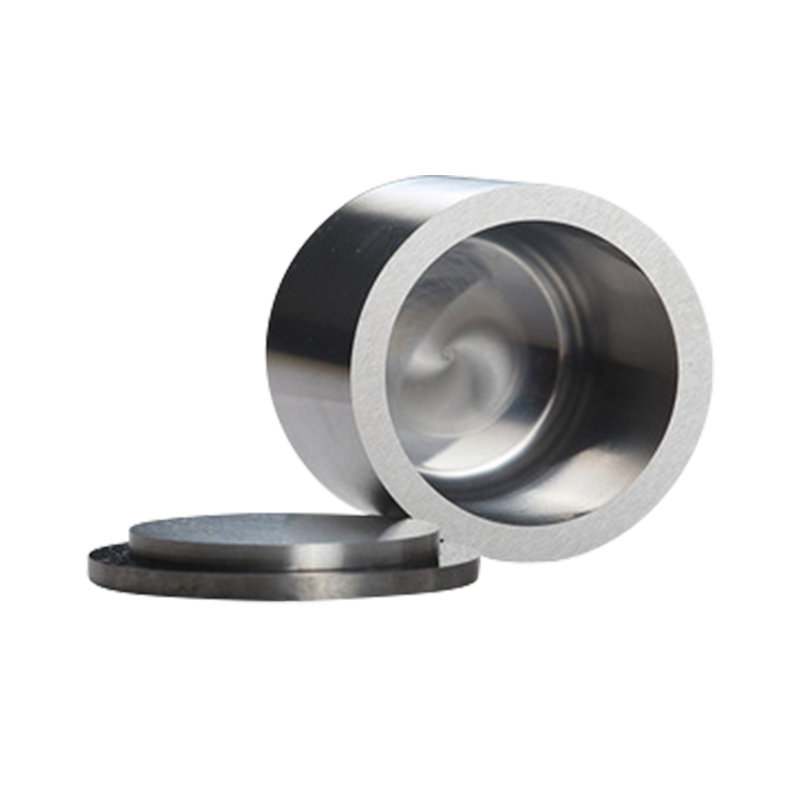

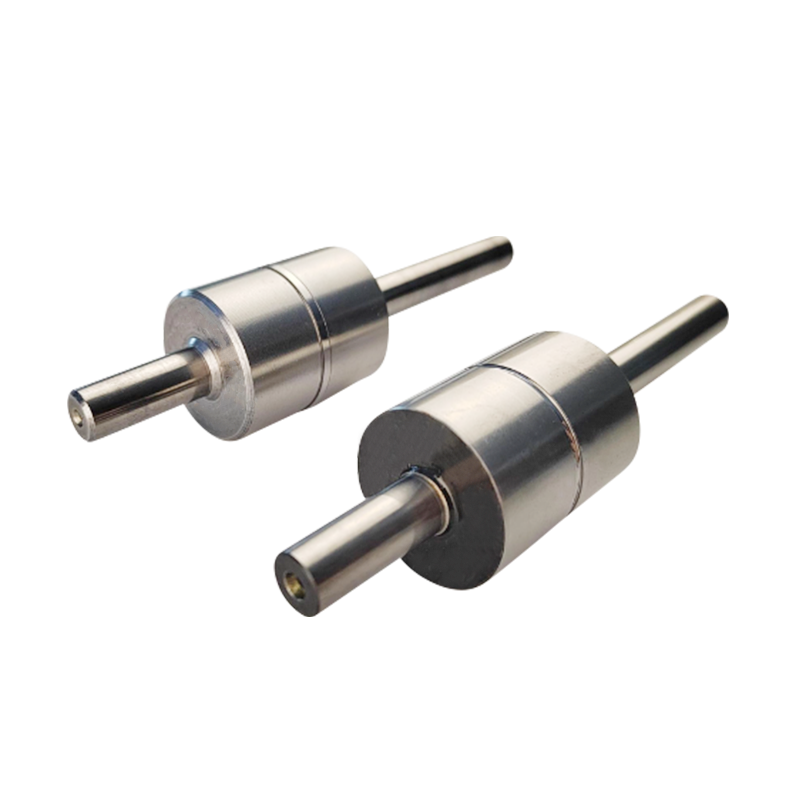

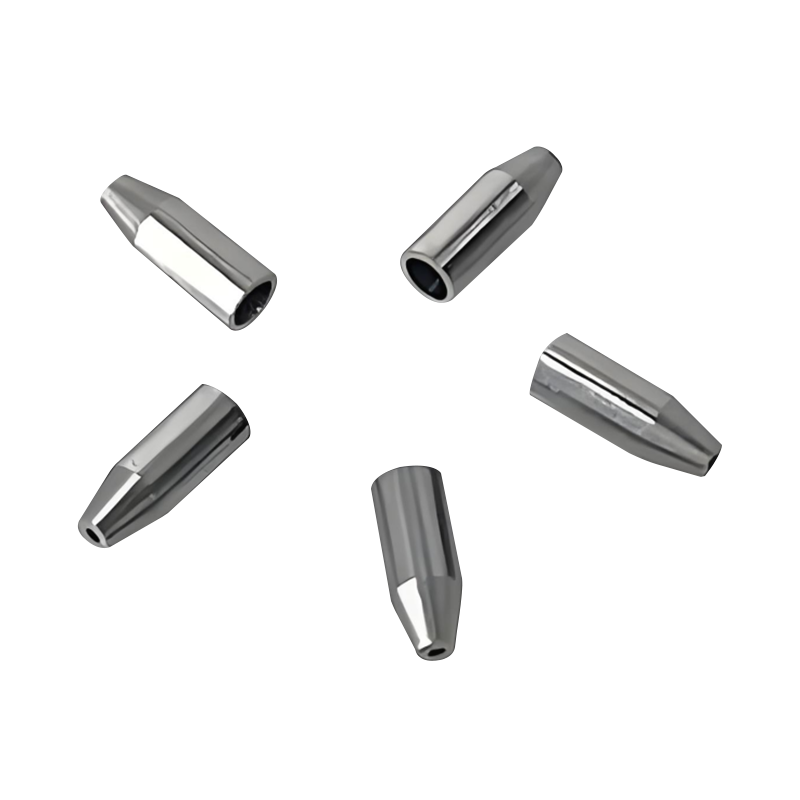

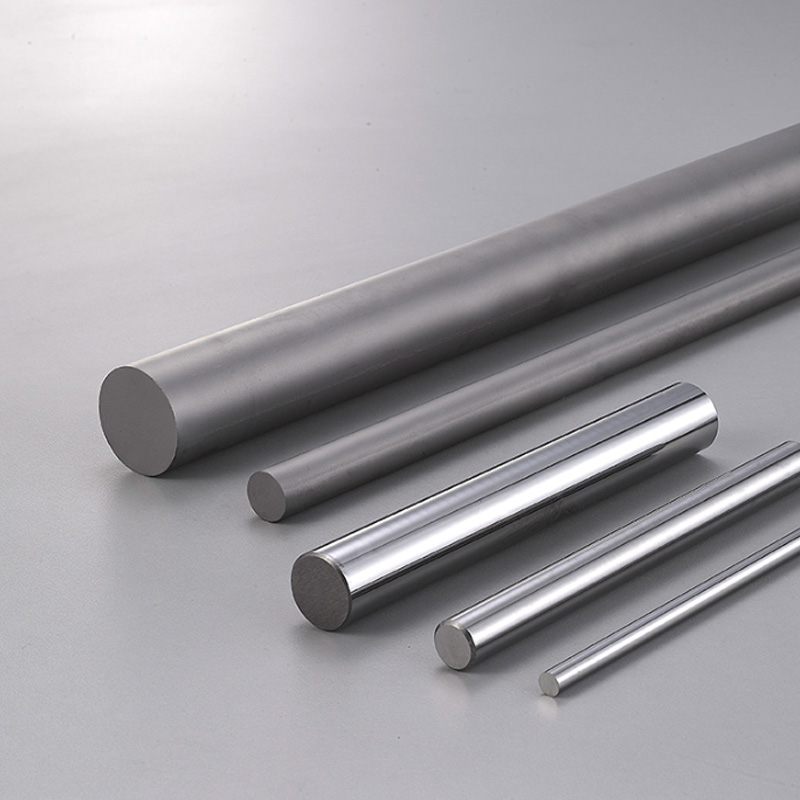

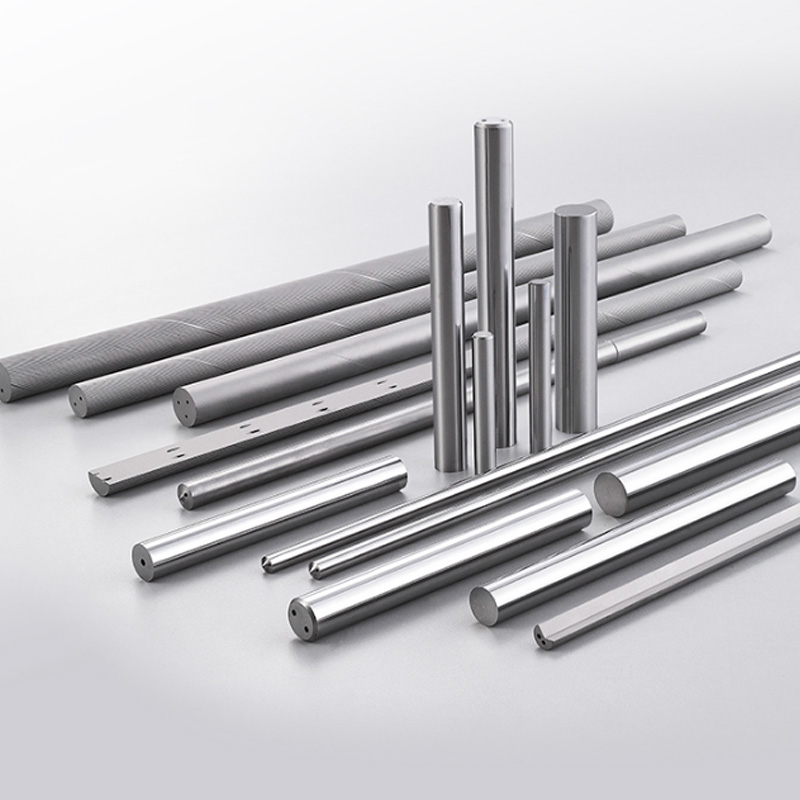

Carbide solidum virga

InquisitioFerreus Alloy rodas sunt cylindrici mox materiae factum per pulveris metallgy technology, quae habent stabilem mechanica proprietatibus, facile Welding, alta gerunt resistentia et excelsum impulsum resistentia. Secundum necessitates ad instrumentum usum, sunt solidum circum virgas ad externum refrigerationem instrumenta, tum unum et duplex rectum foramina, spirae foramina, etc. nam internum refrigerationem tools. Ut late usus est ut instrumentum materiae, ut milling incidunt, terebras, reamers, etc., pro cutting ferus, non-ferrea metalla, plastics, chemical feferas, graphite, speculum, lapis, et Ordinarius ferro. Potest etiam adhiberi ad sectionem difficile ad apparatus materiae ut calor, repugnans ferro, immaculatam ferro, princeps manganese ferro, et instrumentum ferro.

| фD | Tol. | Tol. | Longitudo (0 ,,197) |

| 1/8 | 0,0118 / 0.0177 | H6 / H5 | 13 |

| 3/16 | 0,0118 / 0.0196 | H6 / H5 | 13 |

| 1/4 | 0,0118 / 0.0236 | H6 / H5 | 13 |

| 5/16 | 0,0118 / 0.0236 | H6 / H5 | 13 |

| 3/8 | 0,0118 / 0.0236 | H6 / H5 | 13 |

| 1/2 | 0,0118 / 0.0275 | H6 / H5 | 13 |

| 5/8 | 0,0118 / 0.0275 | H6 / H5 | 13 |

| 3/4 | 0,0118 / 0.0314 | H6 / H5 | 13 |

| 1 | 0,0118 / 0.0314 | H6 / H5 | 13 |

| 1-1 / IV | 0,0118 / 0.0314 | H6 / H5 | 13 |

| 1-1 / II | 0,0118 / 0.0314 | H6 / H5 | 13 |

| фD | Tol. | Tol. | Tol. | H5 tolerantia Minus finis / superius terminum | Longitudo (0, V) |

| H6 / H5 | H6 / H5 | ||||

| 1.3 | 0 / 0.15 | 1.0 | 0 / -0.006 | 0 / -0.004 | 310/330 |

| 2.3 | 0 / 0.15 | 2.0 | 0 / -0.006 | 0 / -0.004 | 310/330 |

| 3.3 | 0 / 0.15 | 3.0 | 0 / -0.006 | 0 / -0.004 | 310/330 |

| 3.8 | 0 / 0.20 | 3.5 | 0 / -0.008 | 0 / -0.005 | 310/330 |

| 4.3 | 0 / 0.20 | 4.0 | 0 / -0.008 | 0 / -0.005 | 310/330 |

| 4.8 | 0 / 0.20 | 4.5 | 0 / -0.008 | 0 / -0.005 | 310/330 |

| 5.3 | 0 / 0.20 | 5.0 | 0 / -0.008 | 0 / -0.005 | 310/330 |

| 5.8 | 0 / 0.20 | 5.5 | 0 / -0.008 | 0 / -0.005 | 310/330 |

| 6.3 | 0 / 0.20 | 6.0 | 0 / -0.008 | 0 / -0.005 | 310/330 |

| 6.8 | 0 / 0,30 | 6.5 | 0 / -0.009 | 0 / -0.006 | 310/330 |

| 7.3 | 0 / 0,30 | 7.0 | 0 / -0.009 | 0 / -0.006 | 310/330 |

| 7.8 | 0 / 0,30 | 7.5 | 0 / -0.009 | 0 / -0.006 | 310/330 |

| 8.3 | 0 / 0,30 | 8.0 | 0 / -0.009 | 0 / -0.006 | 310/330 |

| 8.8 | 0 / 0,30 | 8.5 | 0 / -0.009 | 0 / -0.006 | 310/330 |

| 9.3 | 0 / 0,30 | 9.0 | 0 / -0.009 | 0 / -0.006 | 310/330 |

| 9.8 | 0 / 0,30 | 9.5 | 0 / -0.009 | 0 / -0.006 | 310/330 |

| 10.3 | 0 / 0,30 | 10.0 | 0 / -0.009 | 0 / -0.006 | 310/330 |

| 10.8 | 0 / 0,30 | 10.5 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 11.3 | 0 / 0,30 | 11.0 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 11.8 | 0 / 0,30 | 11.5 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 12.3 | 0 / 0,30 | 12.0 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 12.8 | 0 / 0.40 | 12.5 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 13.3 | 0 / 0.40 | 13.0 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 13.8 | 0 / 0.40 | 13.5 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 14.3 | 0 / 0.40 | 14.0 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 14.8 | 0 / 0.40 | 14.5 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 15.3 | 0 / 0.40 | 15.0 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 15.8 | 0 / 0.40 | 15.5 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 16.3 | 0 / 0.50 | 16.0 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 16.8 | 0 / 0,50 | 16.5 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 17.3 | 0 / 0,50 | 17.0 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 17.8 | 0 / 0,50 | 17.5 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 18.3 | 0 / 0.50 | 18.0 | 0 / -0.011 | 0 / -0.008 | 310/330 |

| 18.8 | 0 / 0.50 | 18.5 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 19.3 | 0 / 0.50 | 19.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 20.3 | 0 / 0,50 | 20.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 21.3 | 0 / 0.50 | 21.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 22.3 | 0 / 0.50 | 22.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 23.3 | 0 / 0,50 | 23.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 24.3 | 0 / 0.50 | 24.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 25.3 | 0 / 0.50 | 25.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 26.3 | 0 / 0.50 | 26.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 27.3 | 0 / 0.50 | 27.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 28.3 | 0 / 0.50 | 28.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 29.3 | 0 / 0.50 | 29.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 30.3 | 0 / 0.50 | 30.0 | 0 / -0.013 | 0 / -0.009 | 310/330 |

| 31.3 | 0 / 0.50 | 31.0 | 0 / -0.016 | 0 / -0.011 | 310/330 |

| 32.3 | 0 / 0.50 | 32.0 | 0 / -0.016 | 0 / -0.011 | 310/330 |

| 33.3 | 0 / 0.50 | 33.0 | 0 / -0.016 | 0 / -0.011 | 310/330 |

| 34.3 | 0 / 0.50 | 34.0 | 0 / -0.016 | 0 / -0.011 | 310/330 |

| 35.3 | 0 / 0.50 | 35.0 | 0 / -0.016 | 0 / -0.011 | 310/330 |

| 36.3 | 0 / 0.50 | 36.0 | 0 / -0.016 | 0 / -0.011 | 310/330 |

| 37.3 | 0 / 0.50 | 37.0 | 0 / -0.016 | 0 / -0.011 | 310/330 |

| 38.3 | 0 / 0.50 | 38.0 | 0 / -0.016 | 0 / -0.011 | 310/330 |

| 39.3 | 0 / 0.50 | 39.0 | 0 / -0.016 | 0 / -0.011 | 310/330 |

| 40.3 | 0 / 0.50 | 40.0 | 0 / -0.016 | 0 / -0.011 | 310/330 |

| 45.3 | 0,20 / 0,70 | 45.0 | 310/330 | ||

| 50.3 | 0,20 / 0,70 | 50.0 | 310/330 |

| Pario | Gradus | June Price Sept. Price (KG / USD) | June Price Sept. Price (Pages / kg) | Frumea magnitudine (Um) | Cobalt contentus (CO%) | Durities (HRA) | Durities (HV30) | Densitas (G / cm 3 ) | Tr (N / mm 2 ) | Applicationem commendatae |

| Ultrafine | Hu12u | 362 | 49.29 | 0.4 | 6 | 93.8 | 1900 | 14.8 | 3900 | Applicata ad altus-duritia materiam dispensando inter PCB terebras, milling incidet, et grave. |

| Hu18u | 387 | 52.69 | 0.4 | 9 | 93 | 1850 | 14.5 | 3900 | Applicata ad dispensando duritiam et difficile-to- Machina materiae, immaculatam machining et micro drometem. | |

| Hu24u | 392 | 53.37 | 0.4 | 12 | 92.6 | 1760 | 14.12 | 4200 | Special Carbide materiale de summus celeritas milling applicantur ad Alloy ferro (Hrc50-60) et immaculatam ferro. Non-ferrea metallum. Titanium Alloy, High-temperatus Alloy, etc. | |

| Hu20x | 375 | 51.06 | 0.6 | 10 | 92.2 | 1730 | 14.43 | 3800 | Nam communem usum summus celeritas milling et EXERCITATIO, applicata Steel steel enim, immaculatam ferro, mittent ferrum, non-ferrea metallum, High-temperatus moxy etc. | |

| Submicron | Hu20 | 372 | 50.65 | 0.7 | 10 | 91.9 | 1600 | 14.45 | 3800 | Nam communem usum milling et EXERCITATIO, applicari ad stone ferro. Immaculatam ferro, non-ferrea metallum, summus temperatus Alloy, etc. |

| Hu20e | 362 | 49.29 | 0.7 | 10 | 91.8 | 1600 | 14.45 | 3700 | Generalis usum oeconomicae milling et EXERCITATIO, applicata Nam steel, immaculatam ferro, non-ferrea metallum, princeps Temperatus Alloy etc. | |

| Hu12 | 361 | 49.15 | 1 | 6 | 92.5 | 1740 | 14.85 | 3000 | Optimus materia ad Diamond Pectus coating, idoneam fibra Reinforced Material (Carbon Fiber et Vitrum fibra): Composita materia, summus Silicon Aluminium Alloy et Graphite products. | |

| Hf30f | 329 | 44.79 | 0.8 | 10 | 91.8 | 1600 | 14.3 | 3500 | Et oeconomica gradu ad milling applicari ad Alloy Steel, non- ferrea metallum etc. |

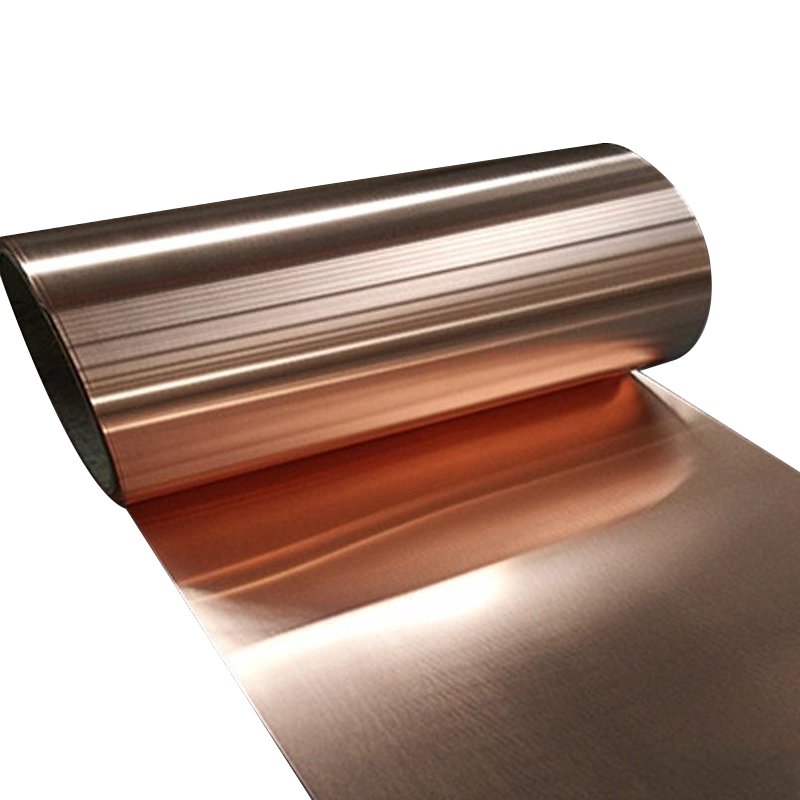

Wenzhou Hongfeng Electrical Alloy Co., Ltd. (Hereñafter ad quod "Wenzhou Hongfeeng"), Foil Foil Metals, Metal Customers et Development ut pars fabrica et intelligentes vestibulum. Noster products sunt late applicantur in industriae vestibulum, intelligentes transportation systems, dolor domos, communicationis notitia, aerospace, Mining, machinery Service, Effectly ad Customer Service, et Delicta Delivery: In addition, possumus etiam providere professionalem materiam consilio, processus optimization, sample praeparatione temptationis, massa productio copia, et technica firmamentum per officia ut professional material consilio, processus optimization et technica. Occursum Customer indiget summus perficientur stanica materiae.

-

Materials Design

Materials Design

Et developmentDesign et progressionem de novus mixturae muneris composita materiae potest ferri ex ut mos necessitates et applicationem elit.

-

Processu

Processu

OptimizationIn vestibulum processus of novus Alloy muneris compositum materiae potest esse optimized pro customers.

-

PRAECEPTIO

PRAECEPTIO

Et temptationisNon possum providere customers cum sample praeparatio et testing servicia pro novus mixturae muneris composita materiae.

-

Moles productio

Moles productio

SuppleSemel novus massa composita materials sunt massa, produci et praebere firmum et reliable copia.

-

Support technica

Support technica

Et consultingHongfeng potest etiam providere pertinet technica firmamentum et consulting servitiis ad customers.

LENTITUDO

LENTITUDO